January 26, 2022

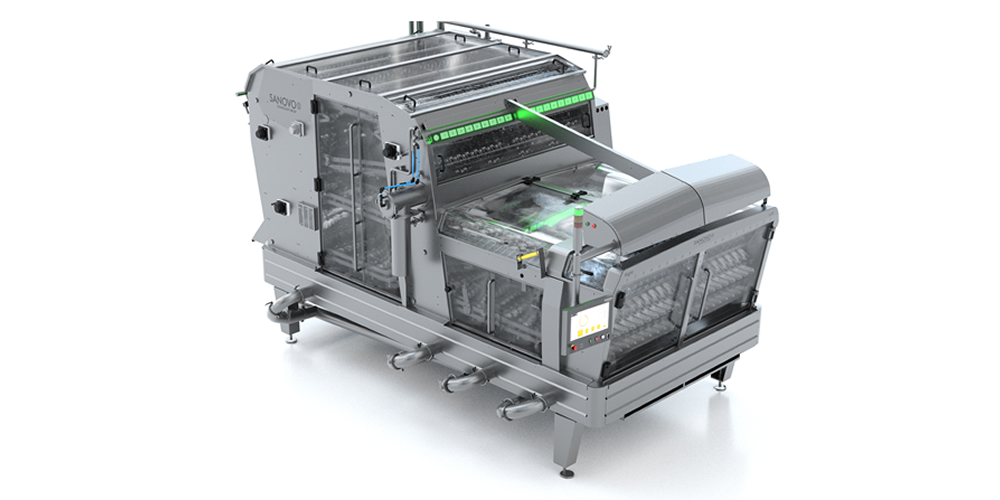

Sanovo debuts BreakerPro egg breaker that can achieve high yield

Sanovo has revealed its latest product, the BreakerPro egg breaker, that is said to provide the highest yield, enabling world-class performance of egg processing plants while also protecting the environment.

"With the BreakerPro, we improve our customers business while optimising the environmental impact of the machine, including the reduction of food waste, which supports an important measure within the UN sustainable development goals," the company said.

"(Can) an egg breaking machine live up to these ambitions? Yes, and we can define four points of how the BreakerPro does that."

These four points are:

- Reduced loss of egg white from dripping into wastewater: The yolk cup has been optimised with a new angle and depth to eliminate sliding yolks. This results in less product spillage and better overall product quality for customers. Sanovo uses food grade polyethylene cups instead of stainless-steel cups, due to various advantages, such as better egg white scanning due to less light reflection and up to 40% lower power consumption due to the lower weight;

- Reduced loss of egg white from shells: The BreakerPro can be equipped with the newly developed egg white recovery unit. It retrieves the egg white hangers sticking to the shells before they are disposed from the breaker. The recovered egg white can now be processed as edible, resulting in up to 0.5% yield increase. With the integrated shell backstop on the optimised egg cracking units, the yield can even be increased by up to 1% in total;

- Reduced need for water and consumables during cleaning: With the BreakerPro, Sanovo managed to eliminate the separate tank and the external piping system for the CIP. The bottom of the BreakerPro is designed as reservoir, resulting in a 15% reduction of water and a 50% reduction of chemical usage. As an option, a separate pre-flush tank can be installed reducing the water consumption as much as 40%;

- Increased user-friendliness for easier machine operation - The HMI has been completely revolutionised, with a 15.6" multi color touch panel and easier log-on access through an RFID access card, which can be configured individually for different access levels. Operators will have a clear overview of the capacity and the filling rate. Moreover, operators can access to manuals directly via the HMI, where they will find any operational data needed. Furthermore, spare part drawings and maintenance-videos can be viewed.

The BreakerPro was tested in a live production area as with all products designed and produced by Sanovo Technology Group.

BreakerPro product page: https://www.sanovoegg.com/products/processing-solutions/breaking/breakerpro-18/

- Sanovo